Motor Controller Enclosure

The motor controller I selected for my electric boat conversion is the VESC 75/300. It met the voltage and current requirements and I was impressed with the openness of the project. The main downsides for me are 1) it is not water protected and 2) the high current connections are made with multiple wire pigtails per terminal. Some people have potted the board for water protection but I did not like the idea of potting around the USB connector or the other control connectors. I chose to build my VESC into a secondary enclosure.

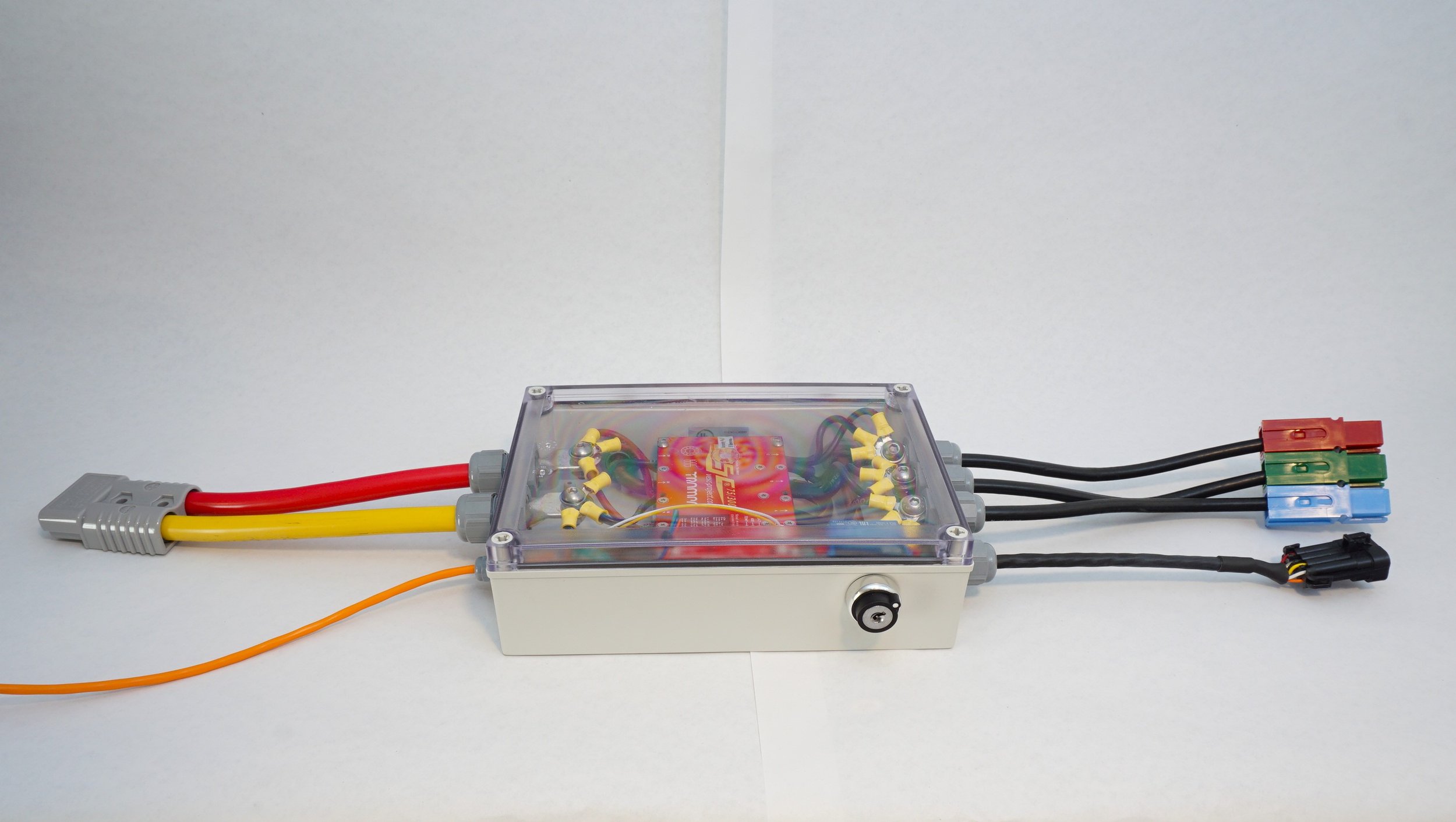

I started with a COTS project box and cable glands. This was suitable for initial bench testing but had some downsides. Most importantly, my first approach to a water cooling block for the VESC has insufficient cooling capacity and does not target the specific heat generating regions of the VESC. Also, the first enclosure still used pigtail cables which made integration a bit troublesome.

My second approach is a fully custom enclosure with a superior water cooling plate design and all panel mount connectors.

First prototype enclosure

First prototype enclosure

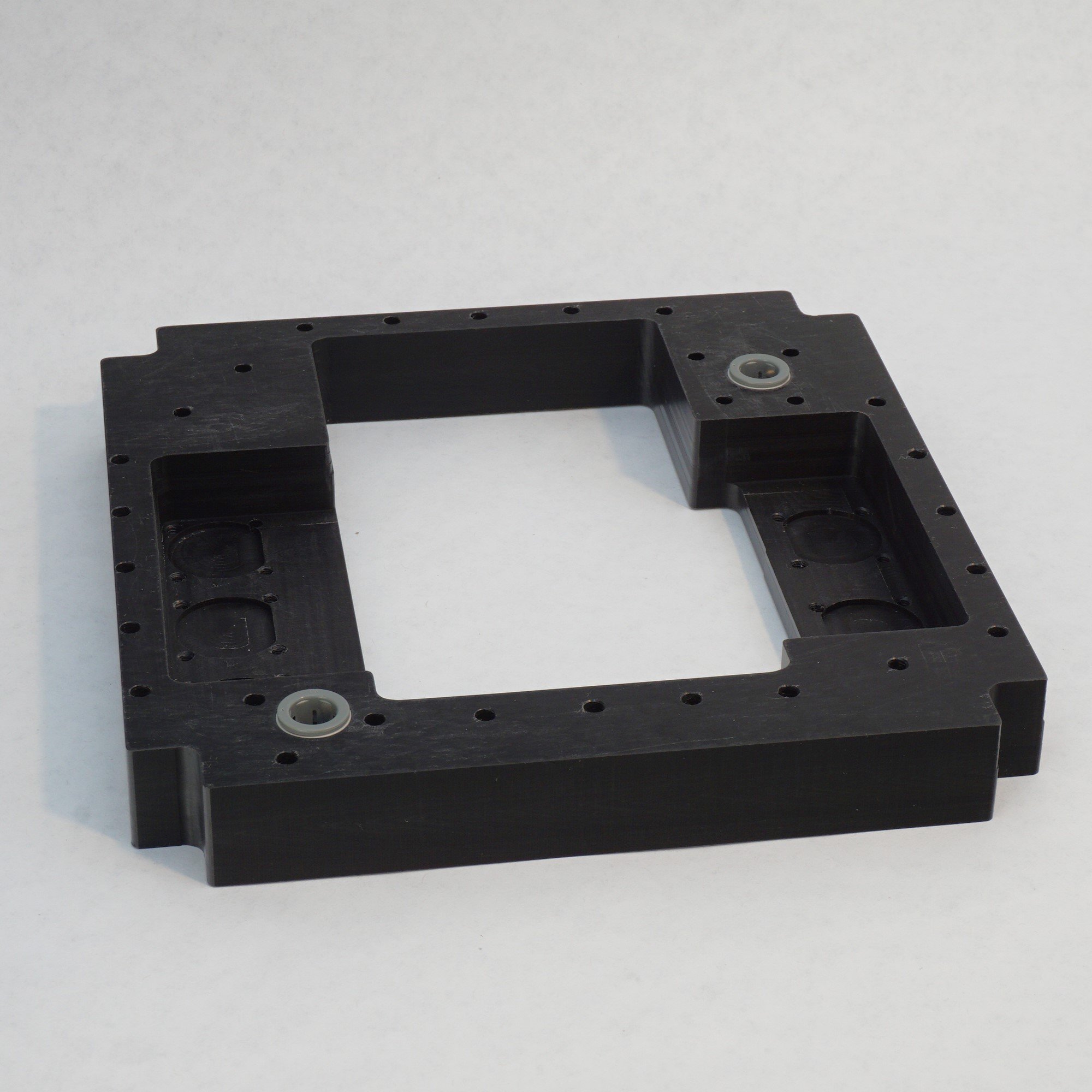

Second enclosure

Second enclosure

Enclosure body. Machined from Delrin. Uses drill-and-install push-to-connect fittings for the coolant channels. These channels pass through this block and seal to the base plate with o-rings inset into the bottom of the block.

Enclosure lid. Machined from Polycarbonate sheet. Includes machined channel for o-ring cord seal. The mounting hole pattern is overkill. The seal works with half the screws in place and a thicker lid would allow even fewer.

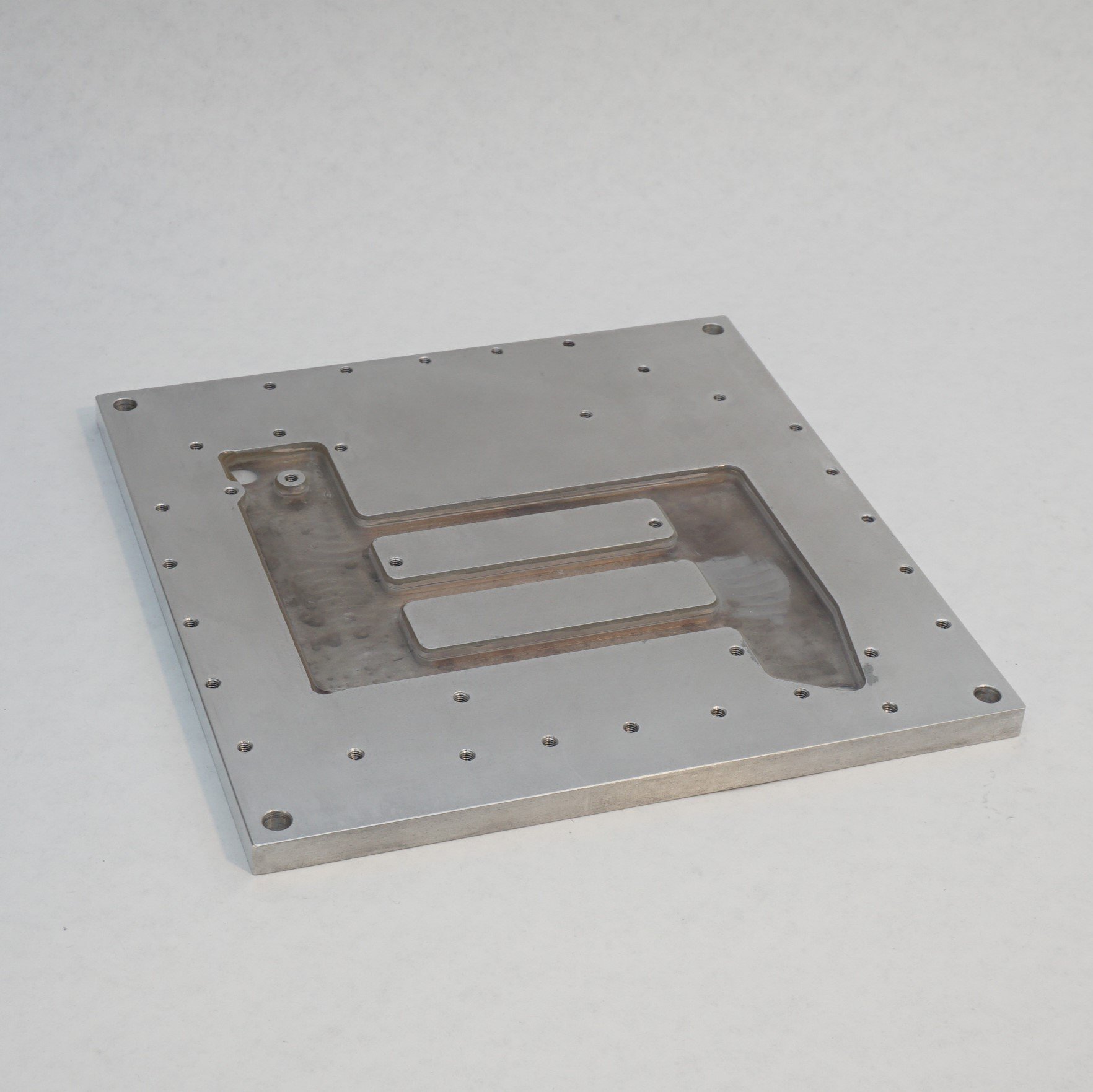

Enclosure base plate and cold plate. Machined from MIC-6 plate for superior flatness where VESC mounts.

Back side of base plate. Fluid channels are aligned with the high current gates on the VESC. The fluid channels are formed by machining a pocket into the base plate then epoxying in a polycarbonate cover plate.

Custom high current electrical connectors. Machined from Copper 110 and electroless Nickel plated. These convert from three wire from VESC to one pad for bolting a cable lug. There is an o-ring groove around the top for sealing to the lid. There is a clamping groove around the base for holding them in place in the body.

CAD exploded view